Setting Up Locations Within a Warehouse

Please access the website version to use this feature

When a warehouse is created, the system generates storage locations within that warehouse corresponding to the warehouse code. A warehouse here functions like a warehouse address containing various storage locations within. You can add additional storage locations within that warehouse or rename the storage locations to suit your business needs.

- Setting Up Locations Within a Warehouse

To set up storage locations within a warehouse, simply follow these steps:

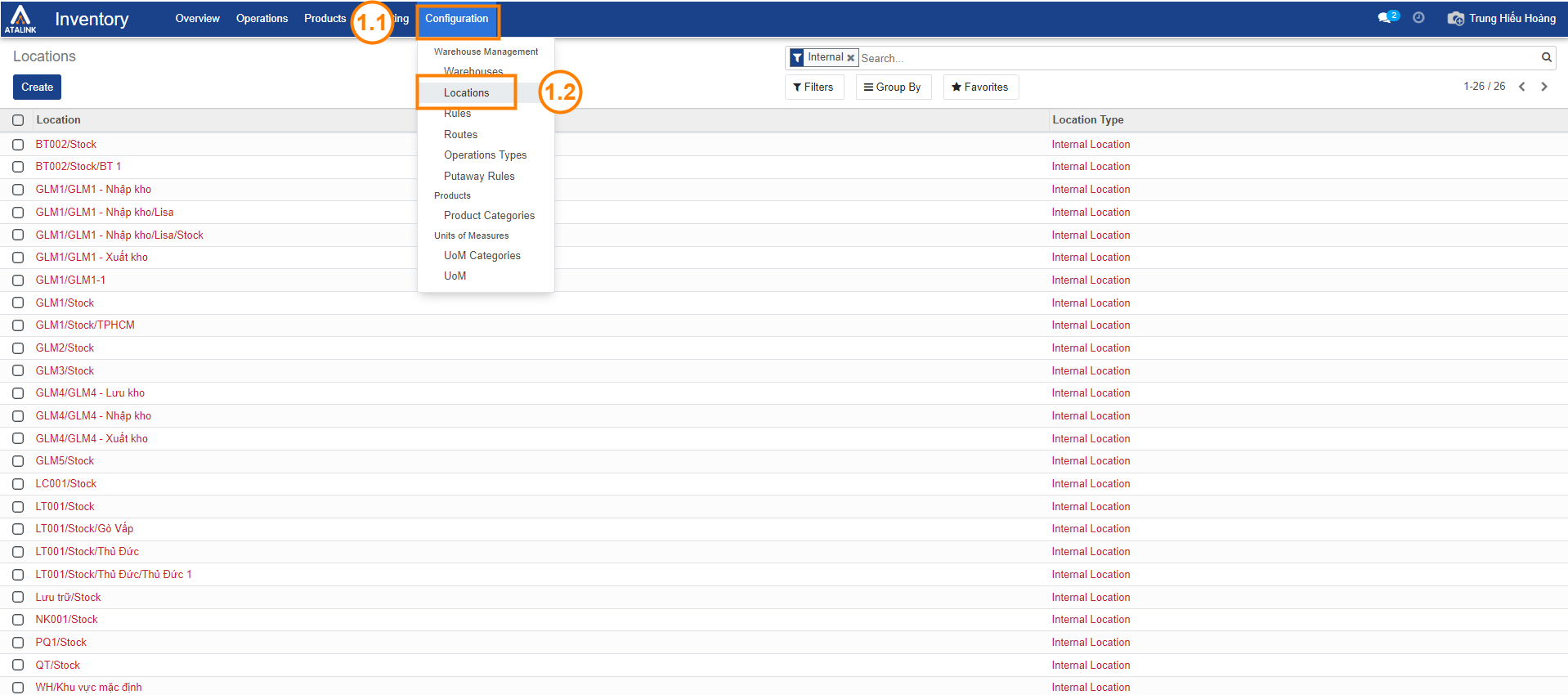

Step 1: Select Configuration > then choose Locations to access the list of locations.

Step 2: Choose Create to create a new location, or select an existing location to edit.

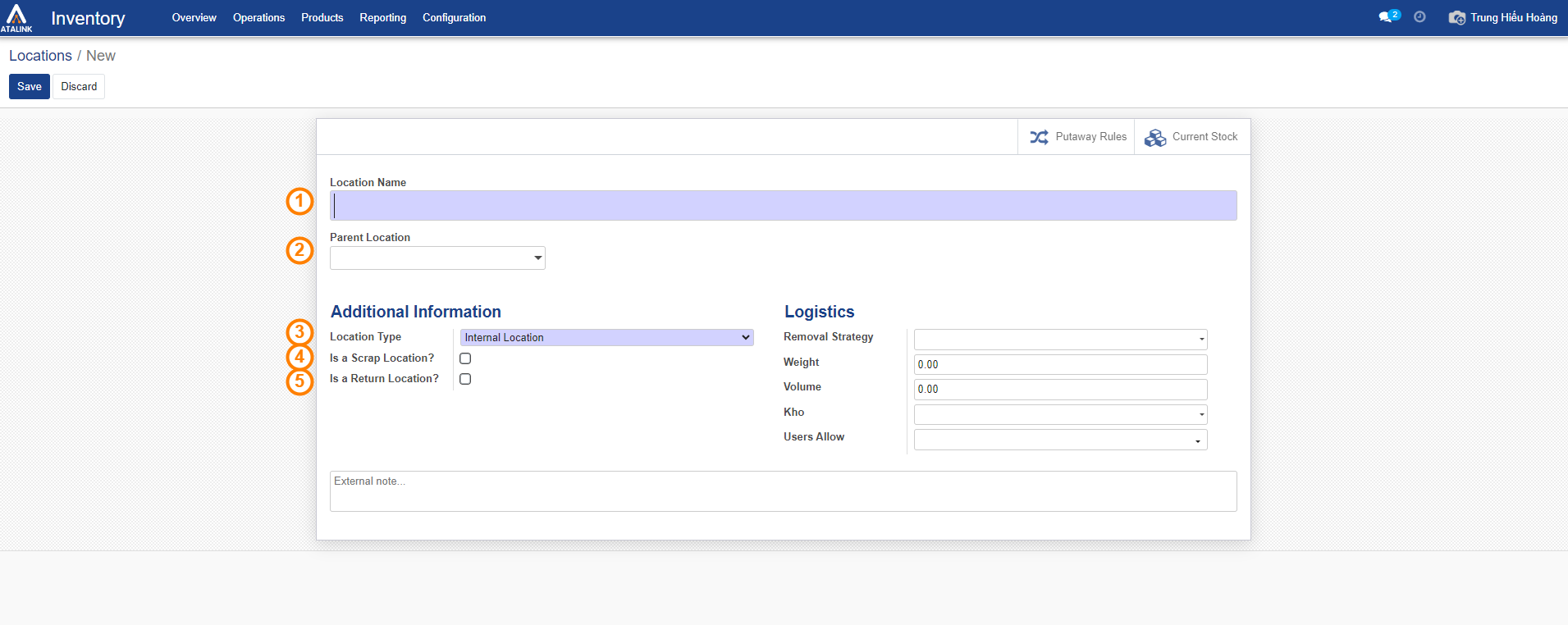

- Location Name: Enter the name of the warehouse location.

- Parent Location: Here you can choose an existing parent location or create a new one.

- Location Type: Choose the appropriate location type. The following types are available:

- Supplier Location: Used as a counterpart for receiving goods from suppliers into the warehouse. For example, from Supplier to Internal Location.

- View Location: Goods cannot be stored in this location. It’s often used to consolidate internal locations. In the given example, if all 3 locations (Reserve, Input, Output) belong to a view location, viewing the total quantity in these 3 locations would only require checking the view location’s quantity, rather than manually summing the quantities of the 3 individual locations.

- Internal Location: Physical locations for storing goods. These locations can have a hierarchical structure, for instance: Reserve Shelf 1 / Compartment 1; Shelf 1 / Compartment 2; Shelf 2 / Compartment 1; Shelf 2 / Compartment 2; etc.

- Customer Location: Used as a counterpart for delivering goods from the warehouse to customers. For example, from Internal Location -> to Customer.

- Scrap/Inventory Location: Used as a counterpart for scrap/audit activities. Lost items during audits generate transfers from Internal Location -> Scrap Location; excess items generate transfers from Scrap Location -> Internal Location.

- Production Location: Used as a counterpart for production activities.

- Transfer Location: Used as a counterpart for inter-warehouse transfers.

- Is a Scrap Location: Check this if the location is used for returning damaged items.

- Is a Return Location: Check this if the location is used for returns.

Step 2: Choose Create to create a new location, or select an existing location to edit.

- Location Name: Enter the name of the warehouse location.

- Parent Location: Here you can choose an existing parent location or create a new one.

- Location Type: Choose the appropriate location type. The following types are available:

- Supplier Location: Used as a counterpart for receiving goods from suppliers into the warehouse. For example, from Supplier to Internal Location.

- View Location: Goods cannot be stored in this location. It’s often used to consolidate internal locations. In the given example, if all 3 locations (Reserve, Input, Output) belong to a view location, viewing the total quantity in these 3 locations would only require checking the view location’s quantity, rather than manually summing the quantities of the 3 individual locations.

- Internal Location: Physical locations for storing goods. These locations can have a hierarchical structure, for instance: Reserve Shelf 1 / Compartment 1; Shelf 1 / Compartment 2; Shelf 2 / Compartment 1; Shelf 2 / Compartment 2; etc.

- Customer Location: Used as a counterpart for delivering goods from the warehouse to customers. For example, from Internal Location -> to Customer.

- Scrap/Inventory Location: Used as a counterpart for scrap/audit activities. Lost items during audits generate transfers from Internal Location -> Scrap Location; excess items generate transfers from Scrap Location -> Internal Location.

- Production Location: Used as a counterpart for production activities.

- Transfer Location: Used as a counterpart for inter-warehouse transfers.

- Is a Scrap Location: Check this if the location is used for returning damaged items.

- Is a Return Location: Check this if the location is used for returns.

Step 3: Click on Save to store the information you’ve entered, or select Discard to cancel the information you’ve created.

- Managing Location Setup within a Warehouse

In the interface for setting up locations within a warehouse, Atalink allows you to perform the following functions:

- Click Create to generate a new location.

- Click Location to interact with the chosen location.

- Click Print to print the barcode for the selected location.

- Click Action to execute actions with the selected locations: Export, Store, Unstore, Delete.